Main application

Pharmacy: crushing raw material, granulating moist material, granulating dry material and unqualified medicine; other reused material can be granulated according to the size of granular. Foodstuff: crushing and reusing biscuit; Other: crushing and granulating coarse raw material; crushing and granulating block raw material, decomposing agglomerated raw material.

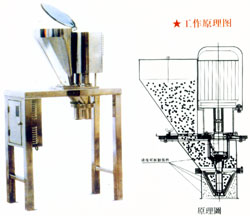

Working principle

The raw material is first poured into the grinding machine and separated by the cone shaped sieves. The rotating cutter stirs up the material in a swirling motion. The raw material particles are then drawn towards the mesh of sieves by centrifugal force. The high-speed rotation of the cutter and the mesh work simultaneously to slice the materials. The particles are crushed into a small powdered state and are ejected out of the pores of the sieves. The size of the powder is determined b the mesh number of the sieve, the distance between the rotating cutter and the sieve and the rotating speed.

technical parameter

|

Item/Model

|

Type 150

|

Type 300

|

Type 450

|

Type 700

|

Type 1000

|

|

Production capacity

|

15-150

|

30-300

|

45-450

|

70-700

|

100-1000

|

|

Granularity (mesh)

|

6-80

|

|

Temperature of transmission seat

|

< 30

|

|

Regulating speed of speed

|

Single speed 2800rpm Frequency conversion 300-3600rpm

|

|

Motor power

|

1.5

|

1.5

|

2.2

|

3

|

5.5

|

|

Overall dimension

|

810×445×1345

|

810×445×1345

|

920×445×1430

|

1000×500×1530

|

1100×560×1785

|

|

Height from discharging gate to ground

|

650

|

650

|

690

|

690

|

565

|