Main application

1. Medicine: granule for pressed disk, granule for filling capsule and so on;

2. Foodstuff: granule for foodstuff making, granule for flavoring;

3. Plastic: shaped granule of all kinds of plastic;

4. Chemical industry: granule of catalyst, pigment, detergent and other chemical raw

materials;

Features:

1. The density of dry powder granule is homogeneous. Its solubility is good. The ratio of granule formed is high.

2. Being adapted special mechanism to feed raw material, it guarantees raw material can be fed effectively.

3. Because its rollers are cooled through circle water, it guarantees the phenomenon of raw material to adhere roller can not be taken place.

4. It is not necessary to use water or ethanol as humectant and to carry out secondary heating and drying. Its procedure is less and its working efficiency is high and its cost is cheap.

5. Being adapted advanced electric hydraulic pressure, its operation is simple and its automatic content is high.

6. Being adapted seal operation, no pollution, the quality of finished product meets the requirement of health.

7. Particularly it is suitable for granulating of raw materials that can not be granulated through damp method.

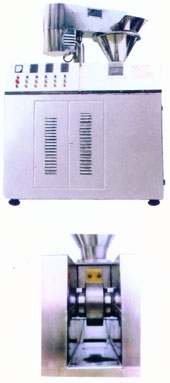

Working principle and use

This machine is new equipment that can granulate from powder to granule directly. Its features are novelty and reasonable in structure, stable and reliable in performance, convenient in cleaning and maintenance. The granule manufactured with this machine can be used for processing tablet, drinking granule, filling capsule, etc.. It is widely used for pharmacy, foodstuff and chemical industry to granulate. Particularly, it is suitable for granulating of raw materials that can not be granulated through damped method.

Technical parameter

|

Model

|

Type 80

|

Type 120

|

Type 200

|

|

Production capacity

|

20-60

|

30-100

|

50-200

|

|

Volume of hopper

|

3

|

5

|

8

|

|

Size of roller

|

200×80

|

200×120

|

250×200

|

|

Max. pre-pressure of roller

|

10×2

|

15×2

|

25×2

|

|

Rotate speed of roller

|

2-20(adjustable)

|

|

Feeding speed

|

6-60(adjustable)

|

|

Motor of driving roller

|

4

|

7.5

|

15

|

|

Feeding motor

|

1.5

|

2.2

|

3

|

|

Granulating motor

|

1.1

|

2.2

|

3

|

|

Drive motor of oil pump

|

0.75

|

1.1

|

2.2

|

|

Max. working pressure of hydraulic system

|

20

|

30

|

50

|

|

Roller and feeding speed

|

Electromagnetic regulating or frequency-conversion regulating

|