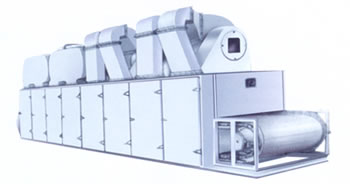

DW series is the first continuous drying equipment developed by our corporation. It is sued for drying the sheet, rod or granular material of good air permeability, and the material of high water content, such as dewatering vegetable, drinking tablet of Chinese traditional medicine and so on; especially for the material that does not permit high temperature. This series dryer has the advantages of quick drying speed, high evaporating strength and high quality. As for the paste material of dewatering residue, it has to granulate it or make it to rod before drying.

Application:

Dehydrated vegetable, granule feedstuff, monosodium glutamate, shredded coconut stuffing, organic pigment, synthetic rubber, PP fiber, medicines, medicinal materials, small wood products, plastic products, aging and solidifying of electronic elements and so on;

Working principle:

Material inside the hopper is spread uniformly by the feeder onto the mesh belt made of 12-60 meshes stainless steel and moved inside the drier by driving devices. Dryer is composed by a few units in which hot air circulates separately and waste air is exhausted by adjustable special fan. During the upper circulation, circulated air enters the lower chamber of the unit and the air flow is heated and distributed to mesh belt in the form of spraying flow before it enters upper chamber through the belt materials. Drying process is the duration of hot air flowing through material layer, where heat and quality is transmitted. The upper chamber is connected by air pipe with fan inlet, in which most part of air circulates except those with low temperature and high humidity which is drained through humidity exhaust. The regulation valve and exhaust fan, In the low circulation unit, circulated air enters upper chamber first, heated by exchanger when down-streams through material layer to the lower chamber which is connected with fan inlet by side air pipes and return air pipes, most part of air circulates with little be drained. Moreover, each unit can be completed freely according to users’ request.

Technical parameter

|

Model

|

Type 1.2-8

|

Type 1.2-10

|

Type 1.6-8

|

Type 1.6-10

|

Type 2-8

|

Type 2-10

|

|

Numbers of unit

|

4

|

5

|

4

|

5

|

4

|

5

|

|

Width of belt

|

1.2

|

1.6

|

2

|

|

Length of drying section

|

8

|

10

|

8

|

10

|

8

|

10

|

|

Spreading thickness

|

10-80

|

|

Working temperature

|

60-130

|

|

Steam pressure

|

0.2-0.8

|

|

Steam exhaust

|

120-300

|

150-375

|

150-375

|

170-740

|

180-500

|

225-600

|

|

Drying time

|

0.2-1.2

|

0.25-1.5

|

0.2-1.2

|

0.25-1.5

|

0.2-1.2

|

0.2-1.5

|

|

Drying strength

|

60-160

|

80-220

|

75-220

|

95-250

|

100-260

|

120-300

|

|

Overall power fo fan

|

9.9

|

12.1

|

9.9

|

12.1

|

18.2

|

22.2

|

|

Overall power of equipment

|

11.4

|

13.6

|

11.4

|

13.6

|

19.7

|

23.7

|